- Préparation

- Take-off

FLYING WHALES – Questions and answers

FLYING WHALES – Questions and answers

What is the concept and overall mission of FLYING WHALES and the LCA60T airship?

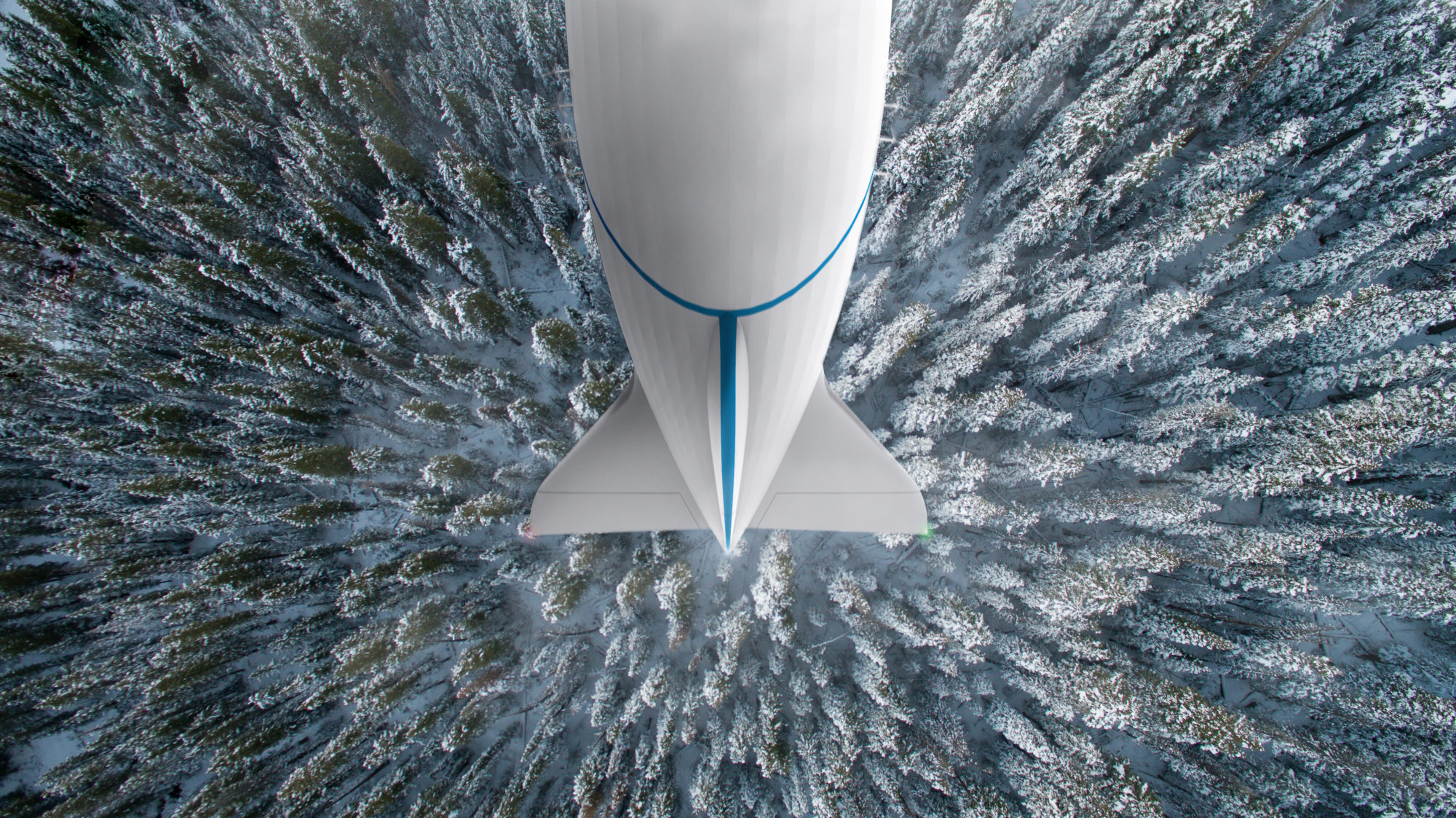

The concept of FLYING WHALES is to develop an innovative air transport solution based on a rigid airship, the LCA60T, capable of carrying heavy and bulky loads (up to 60 tons) without requiring ground infrastructure, thanks to its ability to load and unload while hovering.

FLYING WHALES’ overarching mission is to support the economic development of remote regions while reducing the environmental impact of air freight.

The LCA60T aims to offer an ecological, economical, and flexible point-to-point transport alternative in hard-to-access areas, such as sustainable forestry, construction, wind energy, high-voltage infrastructure, and humanitarian aid, all with a very low carbon footprint.

What are the main technical features and capabilities of the LCA60T?

The LCA60T is a rigid airship measuring 200 m in length and 50 m in diameter, with a cargo bay measuring 96 m long, 7 m high, and 8 m wide. It contains approximately 200,000 m³ of helium distributed across 14 patented cells for aerostatic lift.

It has a maximum payload capacity of 60 tons, which can be transported inside the bay or suspended below it. The airship’s structure and systems weigh a total of 100 tons. Propulsion is hybrid (turbogenerator + batteries) via 32 electric motors arranged around the hull, enabling vertical takeoff, a cruising speed of up to 82 km/h (max 100 km/h), and high maneuverability thanks to distributed electric propulsion and advanced onboard systems.

This allows load/unload operations in hover without ground infrastructure, with a minimal crew of two (pilot and load-exchange officer). Its service ceiling is 3,000 meters, and operations are feasible in specified weather conditions (e.g., winds up to 40 km/h during loading/unloading). Ballast is maintained at a constant 60 tons of water to balance the airship when no cargo is carried.

What is the development, construction, and commissioning timeline for the airship?

Development began in 2012 with the founding of FLYING WHALES, followed by technical studies and consortium formation up to 2017, when formal engineering and aeronautical programming started. Funding rounds took place in 2017, 2019, 2022, and an ongoing one in 2025. Current efforts are focused on system and integration testing.

The subsidiary FLYING WHALES SERVICES, future LCA60T operator, was created in 2024. In July 2025, a public inquiry will be held to obtain the building permit for the Laruscade plant, with construction planned for the second half of 2025. Local recruitment will begin in early 2026, followed by assembly of the first airship in early 2027.

The first flight is expected in 2027, followed by certification ground and flight tests, leading to commercial operations starting in 2029.

What are the expected environmental benefits of using the LCA60T compared to traditional means?

Using the LCA60T achieves significant CO₂ emission reductions, between 60 % and 87 % compared to traditional transports (trucks, helicopters, or planes), especially in areas where infrastructure is lacking or hard to build.

The airship avoids constructing heavy terrestrial infrastructure (roads, forest tracks) that disturb natural environments, thus limiting land artificialization and preserving ecosystems. Its hybrid propulsion, with future potential conversion to low-carbon hydrogen, further reduces the environmental footprint of heavy air freight. Additionally, the high payload capacity reduces the number of trips needed, optimizing overall energy consumption.

How is safety ensured during airship operations?

Safety is guaranteed through high system redundancy, rigorous design conforming to strict aviation standards (EASA, TCCA), and development based on 21st-century certification protocols.

In case of a total power failure, the airship remains airborne like a balloon and can descend safely by releasing helium and water. The loss of a thruster or turbogenerator only marginally affects the mission, and the structure is built to withstand incidents like a propeller blade failure. Multiple helium cells allow for partial loss without immediate danger.

The airship also has a Faraday cage protection against lightning, and ground procedures ensure electrical safety during mooring. The crew always consists of at least two trained members (pilot and load manager) to ensure safe, controlled operations.

Where will assembly plants be located, and how have the sites been chosen?

Three Final Assembly Lines (FAL) will be located worldwide: Nouvelle‑Aquitaine (France) for Europe and Africa, Québec (Canada) for the Americas, and Australia for the Asia‑Pacific region. Site selection was based on key criteria including available land area, proximity to aerospace labor pools, compliance with technical and regulatory constraints (especially aviation safety), and minimized environmental impact.

In France, sixteen potential locations in Nouvelle‑Aquitaine were studied, including turnkey options within the France 2030 framework. A detailed GIS study of the Bordeaux aerospace employment cluster showed Laruscade as the optimal site, meeting essential criteria with minimal environmental footprint. The other two sites were selected using similar analyses.

What local employment impact will the project have and what training will be provided?

The project will ultimately generate 300 direct jobs at the Laruscade plant: approximately 200 FLYING WHALES employees and 100 subcontracted roles, along with another 300 indirect jobs. Roles will span production (assemblers, cable installers, testers), management, quality control, methods, supply chain, engineering, flight testing, logistics, maintenance, safety, and support services (catering, laundry).

Hiring will target experienced professionals, recent vocational diploma graduates, and career changers through local CQPM metallurgical qualifications (approximately five months long). Recruitment will begin in the 12 months leading up to the first airship assembly, with strong local involvement to support regional employment.

How do loading and unloading operations work, especially in challenging weather?

Loading and unloading are performed while hovering, using an innovative winch system to handle cargo inside the bay or slung beneath it for oversized loads.

A mass-exchange system maintains stability by swapping payload with water ballast (approximately 60 tons) using ground tanks. To cope with weather constraints, the airship always aligns with the wind, leveraging 32 electric thrusters to maintain position.

Operations are limited to wind conditions similar to those allowed for cranes or helicopters (maximum 40 km/h). In misaligned or high-wind scenarios, ground-based support is used for safe cargo handling. A weather forecasting software, developed with CNRS, plans operational days based on precise wind and gust predictions.

What is the economic model and how is the project financed?

FLYING WHALES’ economic model is based on providing aerial transport services via its subsidiary, FLYING WHALES SERVICES, which will deploy and operate the operational bases worldwide. In the longer term, it will also sell the LCA60T airships.

Initial funding came from private investors (60 %) and public sources (40 %), with cumulative fundraising of approximately €162 million since 2017, supplemented by grants and R&D tax credits. The full LCA60T development requires an estimated €550-600 million.

The Initial Public Offering is planned around the first commercial flight in 2027, to enable private investors to exit and accelerate scaling. Eventually, the project aims for self‑financing through revenues from logistics services, airship sales, maintenance, training, and a ten‑year business plan with phased global deployment.

Which markets and sectors does the airship target?

The LCA60T is designed for key sectors: wind energy (20 %), forestry/wood (7 %), construction & infrastructure (15 %), heavy industry & logistics (33 %), humanitarian aid & disaster relief (5 %), as well as niche sectors like aerospace (7 %), G2G (government procurement) (7 %), nuclear energy (2 %), and oil & gas (2 %). These sectors require heavy or oversized load transport in hard-to-reach areas, where the airship complements traditional transport.

Independant consulting firm Roland Berger estimates a total market potential of about 750 airships by 2034, with FLYING WHALES’ business plan initially covering 160 units.

How is the LCA60T certified and what challenges does certification entail?

Certification is led by EASA (European Union Aviation Safety Agency), with close collaboration with Canadian TCCA for joint validation, targeting a type certificate by late 2028.

The process comprises four major stages: concept familiarization (2018–2025), requirements definition, certification program development (analyses, simulations, tests, 2022–2026), then compliance demonstration through ground and flight test campaigns (2023–2028). Key challenges include the lack of specific regulations for heavy‑lift airships, requiring the co-development of standards with authorities, and managing technical complexity (composite structure, hybrid propulsion, hover loading systems).

Certification must ensure safety levels comparable to modern aircraft, demanding rigorous testing and precise risk management.

What training is required to pilot and operate the airship?

Pilot training starts with selecting certified airplane or helicopter pilots, who will undergo approximately one month of theoretical instruction on airship operations and ground-crew coordination, followed by five months of practical flight training for initial qualification.

Additional LCA60T-specific training includes two weeks ground school and two months in-flight training. Pilots must hold a Class 1 aviation medical certificate and have aviation English proficiency.

Mechanics will be trained under PART-66 certification, with a dedicated module on gas airships (L5). The FLYING WHALES flight school in Nouvelle‑Aquitaine will train several hundred operators (pilots, load‑exchange officers, ground crew, mechanics) across roles necessary for airship operation.

How does the project address environmental issues?

The project strongly focuses on reducing the ecological impact of heavy transport by avoiding the creation of terrestrial infrastructure (roads, forest tracks) that degrade mountain massifs and fuel deforestation. In partnership with ONF, the airship enables access to otherwise unreachable forests, distributing logging to encourage better regeneration.

Biodiversity compensation measures have been implemented, including habitat restoration for protected species like the European mink and otter, ecological connectivity improvements, invasive species control, and non‑invasive monitoring protocols.

The Laruscade plant site underwent in-depth studies to minimize its footprint through reduced soil impermeabilization, and specific management plans were developed to protect wetlands and Natura 2000 habitats. These measures are backed by scientific partnerships and validated by national environmental authorities.

What are the technological and commercial growth outlooks for FLYING WHALES?

Technologically, FLYING WHALES plans to transition from hybrid turboprop to sustainable aviation fuels (SAF) and ultimately renewable hydrogen, achieving estimated carbon emission reductions of up to 85% compared to traditional methods.

Commercially, global deployment will include construction of FALs in France, Québec, and Australia, accompanied by a fleet of 160 airships across sectors like wind energy, forestry, construction, humanitarian aid, and heavy industry. Growth will be supported by a network of operational bases and the training of thousands of specialized operators.

The company also aims to develop new applications beyond its initial scope, reinforcing its position in an expanding market. A public listing in 2027 will accelerate financing and expansion while solidifying its technological leadership.

What are the main steps and criteria for establishing and deploying operational bases for the LCA60T?

Deployment of operational bases follows a structured four-stage process: market need validation (demand analysis, meteorological studies, business planning); operational feasibility and site identification (technical, regulatory, environmental assessments); financial validation; and finally, base construction and commissioning.

Key site selection criteria include sufficient flat area (about 32 ha, including 2.5 ha for a hangar), compatibility with local aviation activities, favorable weather conditions, and strict environmental impact constraints to protect soil and ecosystems.